Nutrisco

Our

Infrastructure

We have several manufacturing plants dedicated to the production and processing of food from our Seafood, Fruits & Vegetables, and Snacks Units.

Our Infrastructure

Agile and

sustainable supply

Our infrastructure combines advanced technology and experience to ensure efficiency and quality. With plants specializing in seafood, frozen fruits, and snacks, we meet high standards.

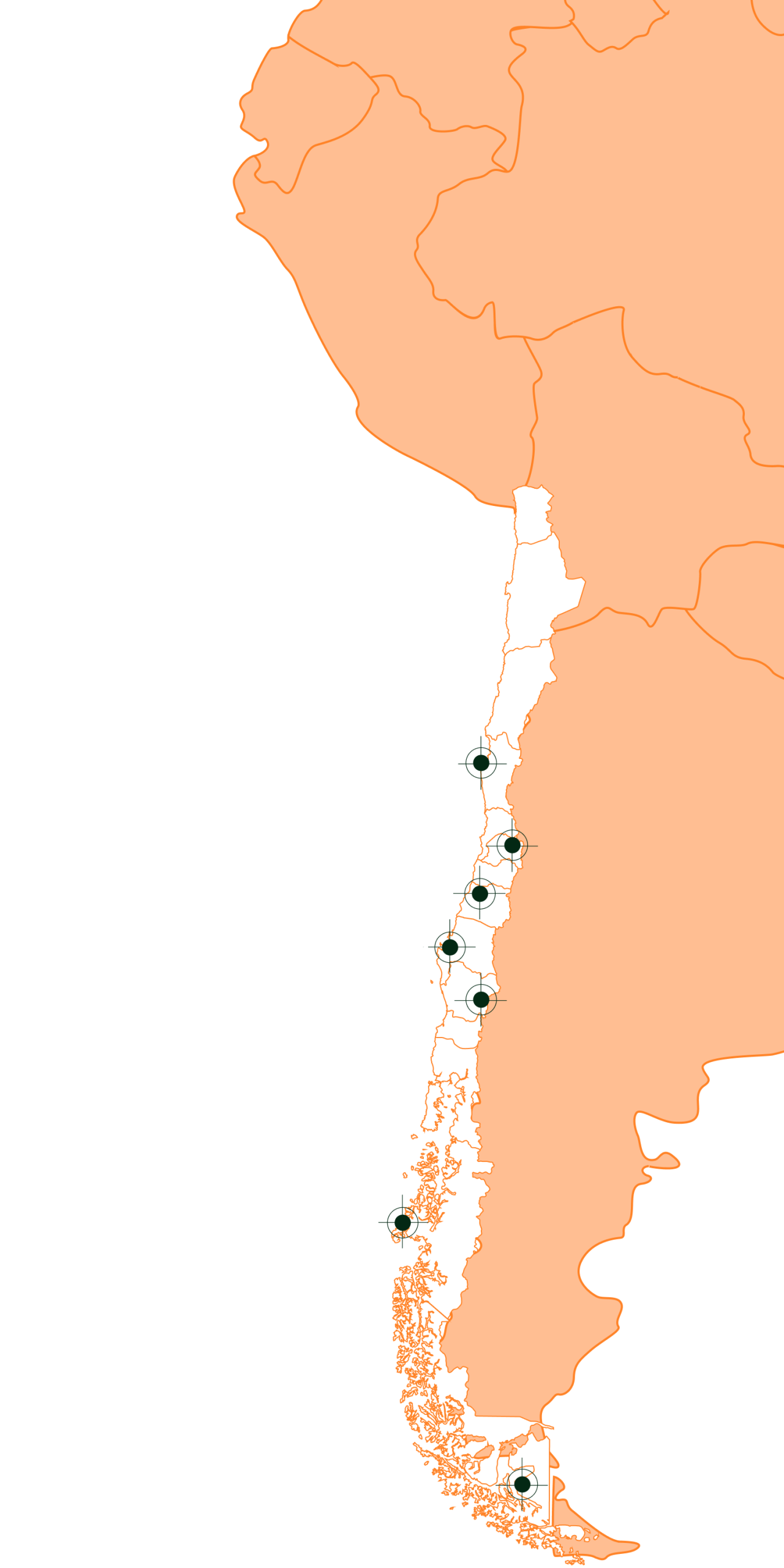

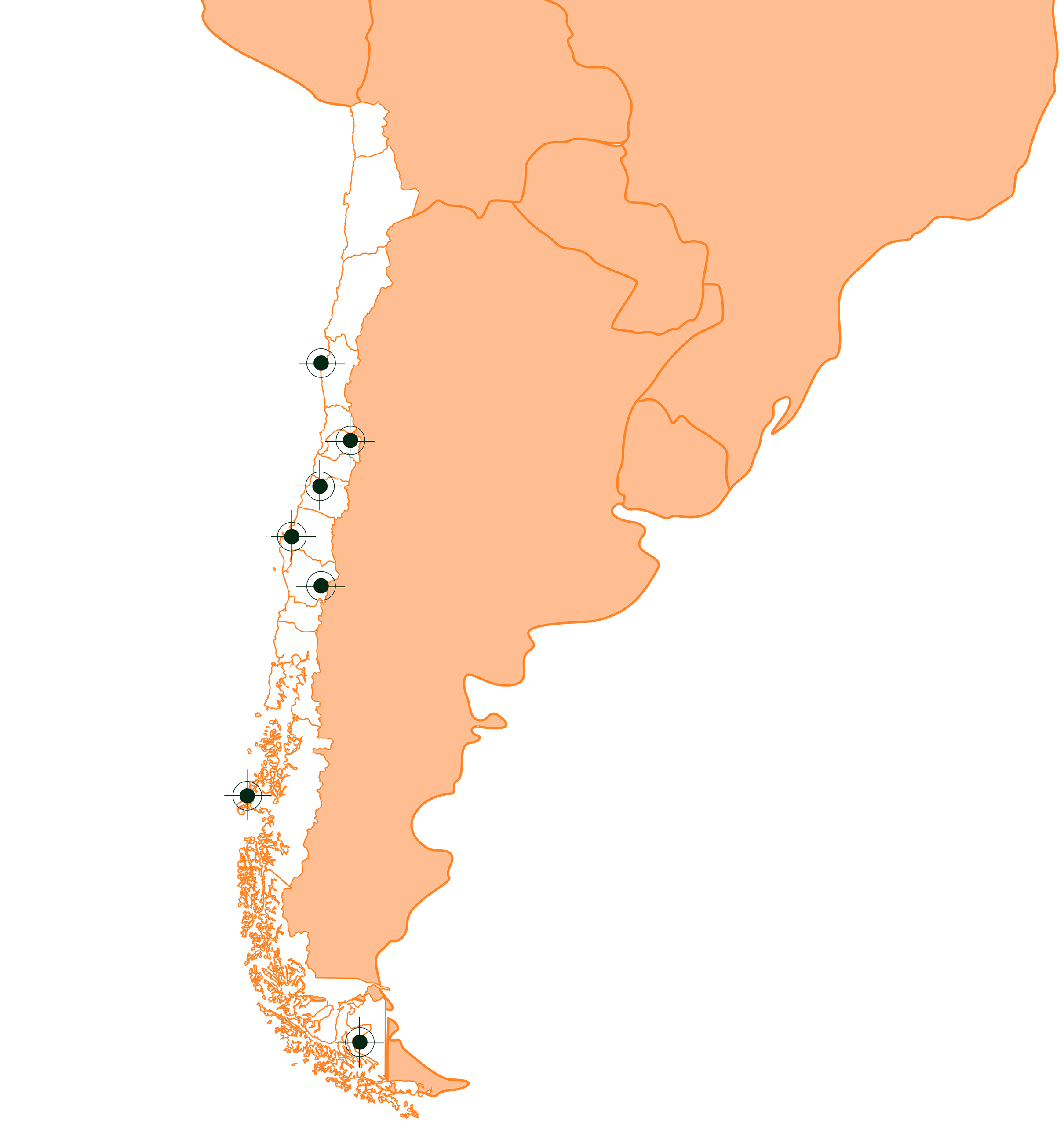

7 floors in total

Manufacturing

plants

Coquimbo

Quilicura

Romeral

Coronel

Angol

Aysén

Porvenir

4 Seafood Plants

Coquimbo

Fishmeal and fish oil plant

Coronel

Industrial fishing complex

Puerto Aysén

Seafood processing plant

Porvenir

Seafood processing plant

2 Frozen Fruits & Vegetables Manufacturing Plants

Romeral

Frozen fruit processing plant

Angol

Frozen raspberry processing plant

1 Snack Manufacturing Plants

Quilicura

Fruit and vegetable chip processing plant

Infrastructure

Seafood

Coquimbo

In Coquimbo, we produce fishmeal and fish oil with a capacity of 220 tons per hour. 50% of the company’s total catch is artisanal, of which 10% comes from Coquimbo.

Additionally, since 2022, it has been operating with 100% renewable energy, reaffirming our commitment to sustainability.

Coronel

The Coronel plant produces 30,000 cases of canned and frozen Jack Mackerel daily, as well as 370 tons of whole frozen Jack Mackerel. In 2021, the “Arctic Project” was implemented to modernize the infrastructure, increasing the processing and storage capacity of frozen products.

Aysén

The plant in Aysén, built in 2002 and renovated in 2019, covers 4,000 m² and features advanced technology valued at US$2 million.

Its processing capacity reaches 30,000 kg per daily shift, establishing itself as a benchmark for efficiency and quality in the region.

Porvenir

The plant in Porvenir, built in 2009, covers 2,500 m² and is equipped with technology valued at US$2 million. It has a processing capacity of 25,000 kg per daily shift, standing out in the production of King Crab and Chilean Seabass for both domestic and international markets.

Infraestructure

Frozen Fruits

and Vegetables

Romeral

At the Romeral plant, we have 4 continuous IQF tunnels and 10 processing lines for retail products, with packaging capacities ranging from 150 to 3,000 grams, as well as a dedicated line for fruit purée production. Our freezing capacity reaches 300 tons per day, and we have a storage system with up to 15,000 positions.

40,000 ton/year.

Angol

Our plant, dedicated to raspberry processing, is located in the very heart of our raspberry fields. With a production capacity of 1,000 tons per season, we ensure that each raspberry reaches its fullest expression, reflecting the love for nature that surrounds our process.

Infraestructure

Snacks

Quilicura

Since 2024, we have been a B Corporation committed to sustainability and social responsibility, offering high-quality products with a positive environmental impact. We operate a plant in Quilicura with unique technology in Chile, enabling a low-temperature frying process that preserves nutrients and reduces oil content by 60%, providing healthier and more delicious options.

Infraestructure

Customer experience

and distribution center.

Distribution

center

Storage: 17,500 positions for dry, refrigerated, and frozen goods.

Flexibility: Ability to quadruple storage capacity in the coming years.

Distribution: Nationwide.

Nutrisco

Market

Physical Stores: 3 locations, in Santiago, Curicó, and Concepción.

eCommerce: 1 online store www.nutriscomarket.cl

Nutrisco

Lab

Interactive Kitchen. More than 500 visitors since it opened.

A space for connection and product development.